MID

Intelligent Manufacturing

- BUSINESS

- CAPABILITIES

- NEWS

- …

- BUSINESS

- CAPABILITIES

- NEWS

MID

Intelligent Manufacturing

- BUSINESS

- CAPABILITIES

- NEWS

- …

- BUSINESS

- CAPABILITIES

- NEWS

MID Intelligent Manufacturing

Precision machining manufacturing

MID Intelligent Manufacturing

Precision machining manufacturing

Professional

Success stems from every detail

ABOUT US

MID Intelligent Manufacturing Co., Ltd, is a precision CNC machining and sheet metal processing manufacturer for high-mix, high-complexity, high-flexibility and small-volume production etc. Our businesses service Aerospace, Medical, Energy, Automotive and Semiconductor OEMs. Our products are exported to North America, Europe, the Middle East, and Asia.

MID, located in Dongguan (the world's manufacturing city) has both design offices and manufacturing plants, totaling 7500 square-meters in size. MID is equipped with over 90% of sophisticated Milling and Turning, Laser, CNC punching & bending equipment from FANUC, Okuma and AMADA etc.. MID , is certified with ISO9001 and ISO13485, and also has comprehensive measurement and inspection capabilities .The future of MID Intelligent is to help customers increase more marketing opportunities by assisting them to develop innovative machining pocess. We built a team that technician with over 30 year’s experience developing high-precision & high-complexity machinging products, project engineers are well trained for project management with PMP certified and also qualified as IATF 16949 auditor. In order to achieve flexible lean production and zero defect, we developed a specialized in-house QES (quality execution system), which follows the concept of traceability management of AS9100.

MID intelligent is not “just another CNC machine shop”,

but a company to help customers increase more marketing opportunities by innovative machining pocess development support.

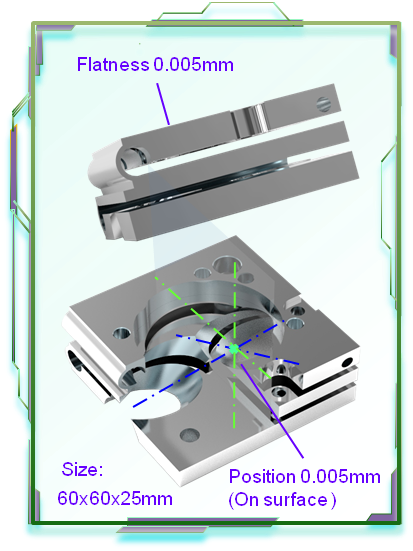

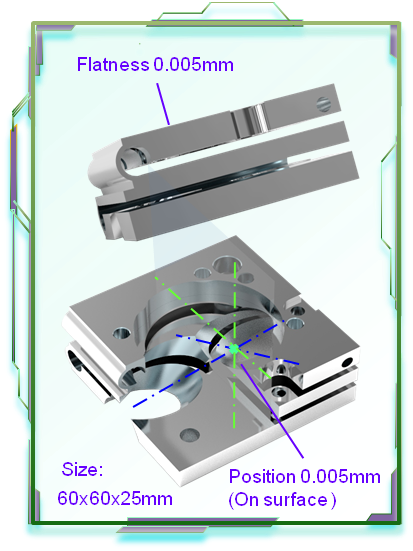

Five-axis machining

Flatness 0.005 mm after finishing

Posituion 0.005mm axis-cross point

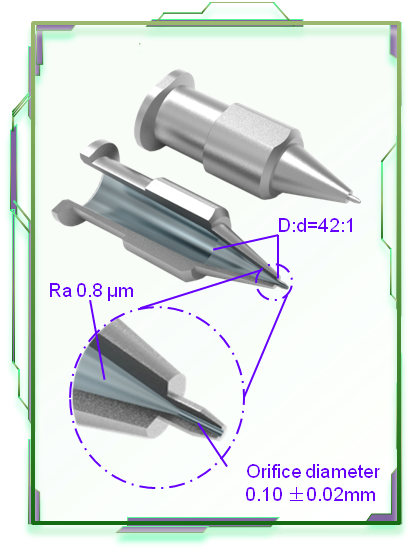

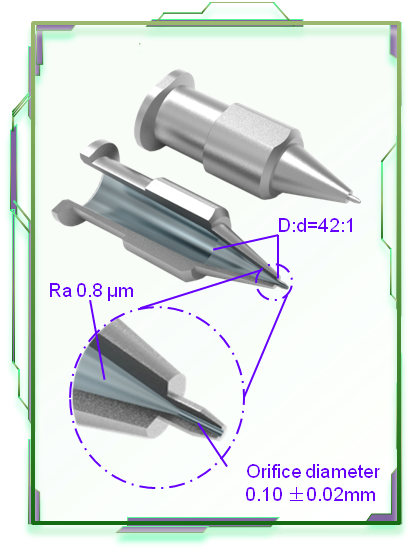

Ra 0.8 μm on inner bore

D:d= 42:1, 0.1mm MIN

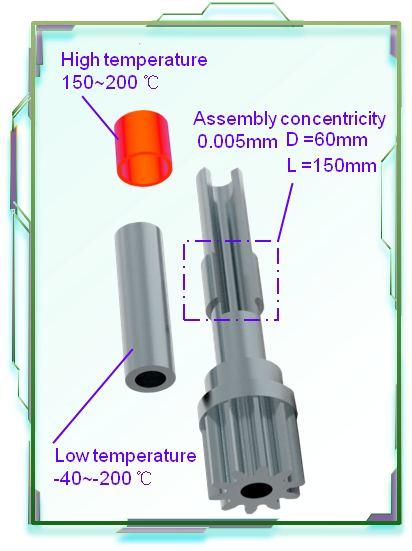

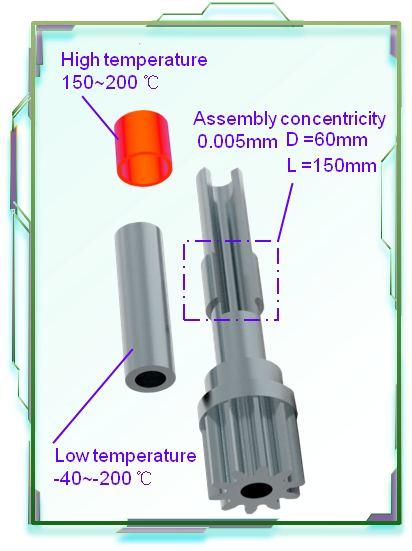

Thermal-gradient assembly

Concentricity 0.005mm

BUSINESS

--Lightweight with high strength & stiffness, high temperature resistance, low temperature resistance, aging resistance, corrosion resistance, tenacity and good fatigue resistance etc..

--Parts are traceable throughout their life cycle ensured by specialized QES (quality execution system) which is based on the concept of traceability management of AS9100.

--High-precision five-axis machines and turn-mill machines to meet aerospace requirements with Hi-Mix low volume, complex structure, tight tolerances, stable quality, and even hard-to-machine metals, typical of aircraft engine components etc.

--Medical

-- ISO13485 certified, with experience on Cosmetic medical equipment, medical equipment, diagnostic medical equipment and others.

--Experience with 6AL-4V processing, which is a widely used material for medical implant devices.

--5S management of clean workshops, special machining cutting tools ensure high precision, removal of burrs and excellent surface finishing.

--Flexible multi-axis machines and automatic lathes meet the requirements of small volume and compact structure high productivity.

--Mid project engineer qualified as a IATF16949 auditor and experienced engineering staff is focused on supporting you from early development throughout production.

--Flexible multi-axis machine and automatic lathes meet the requirements of small volume and compact structure high productivity.

--Machined tolerances are crucial for performance and safety, like gear box system, drive shafts, engine components and valve body etc.

--High flatness & surface quality (linear module guide flatness <0.005mm), ensure smooth transmission, low noise and zero fault in the equipment service life to help customers win a better reputation in market.

--MID intelligent project engineers with rich mechanical knowledge, are able to help our customer discover assembly issues, and provide the solutions for mechanical properties and processing optimization.

--Roughness under Ra0.2 for internal surface, such as valve body, pipe and nozzle, <Ra 0.2, to improve the service life of fluid-related parts

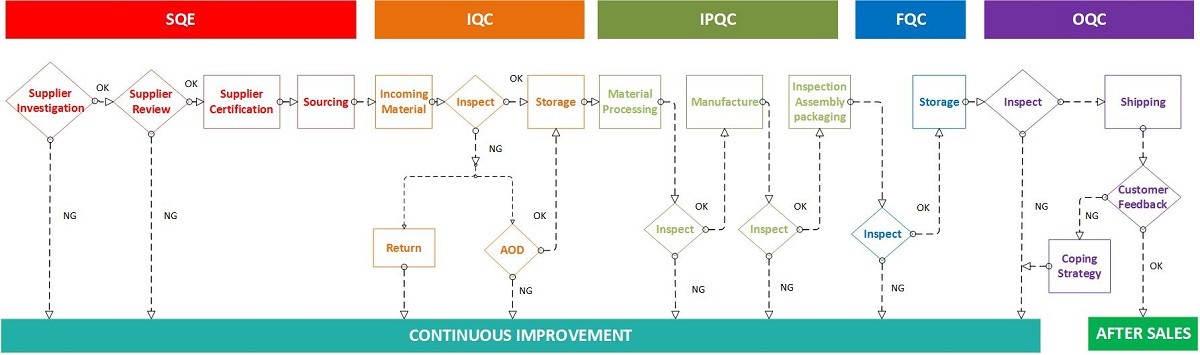

--Quality

- ISO13485 certified

- Traceability QES (Quality Execution System)

-Qualified as a IATF16949 auditor

--Technology

- 30 years’ experience in machining

- Specialize in cutting tools and multi-process solution

- Obtain the utility model patent

--Management

In order to achieve flexible lean production and zero defect, we developed a specialized in-house QES (quality execution system), which follows the concept of traceability management of AS9100.

Newas

你的想法,值得被传递

There are no published blog posts yet.

About us

Know the Mid

Our business

Aerospace Machining & Assembly

Medical care

Energy and automotive

Industrial Printing equipment

Mid (Dongguan) Intelligen Manufacturing Co., Ltd Copyright 2019