MID

Intelligent Manufacturing

- BUSINESS

- CAPABILITIES

- NEWS

- …

- BUSINESS

- CAPABILITIES

- NEWS

MID

Intelligent Manufacturing

- BUSINESS

- CAPABILITIES

- NEWS

- …

- BUSINESS

- CAPABILITIES

- NEWS

MID Intelligent

Manufacturing Co., Ltd

The future of MID Intelligent

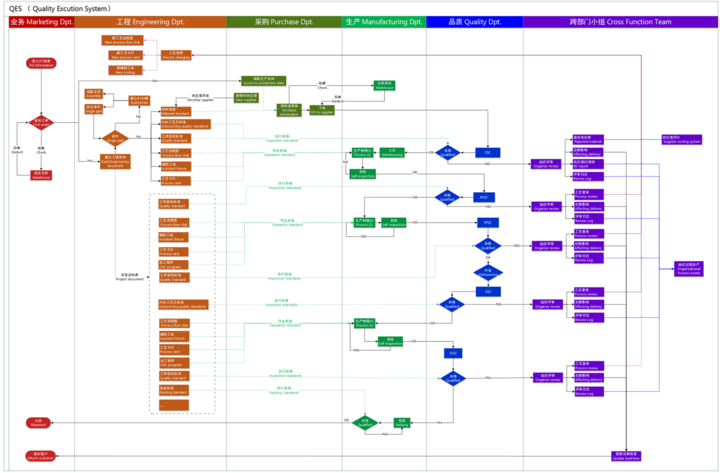

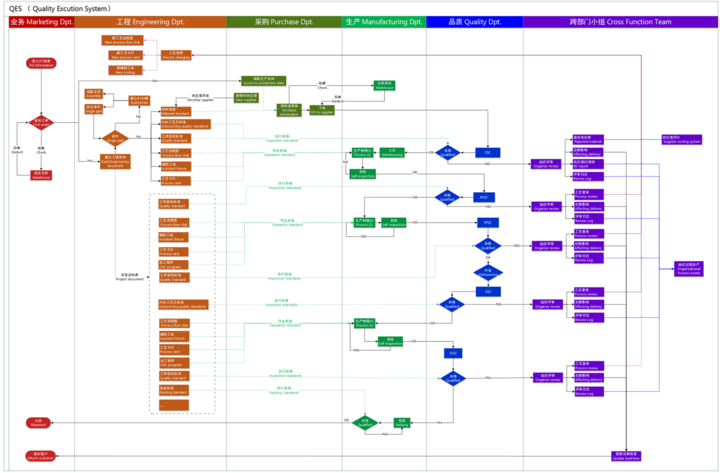

Help customers increase more marketing opportunities by assisting them to develop innovative machining pocess. MID technician gather more than 30 year’s experience developing high-precision & high-complexity products. The project engineers are well trained for project management with PMP certified and qualified as IATF 16949 auditor. In order to achieve flexible lean production and zero defect, we developed a specialized in-house QES (quality execution system) system, which follows the concept of traceability management of AS9100.

The common problems QES to solve

- Avoid repetitive mistakes, the system records every quality abnormal, issue log, the solutions and lesson learned for learning.

- Eradicate cheating for fabricated data to push to the limit of continuous improvement, no access to modify the submitted information which is approved but add a new one record. The date of record is written by system with real-time.

- Avoid incorrect versions, the newest version drawing, standards, and CNC program etc. will be default preferences always. The access would be limited if no standards to follow.

- Reduce waste time on data query for quality traceability or quality system audit.

- Meet customer management needs, the system based on customized flexible open principle.

- Efficient and solution-oriented, system defined work process from the idea of TOC critical chain which is according to company management actual need.

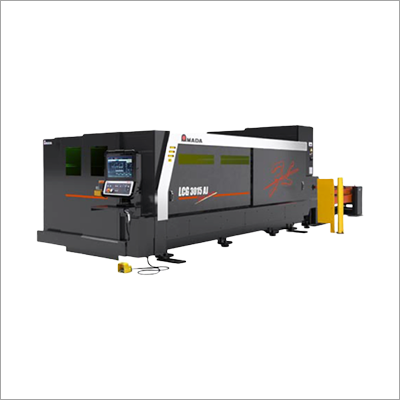

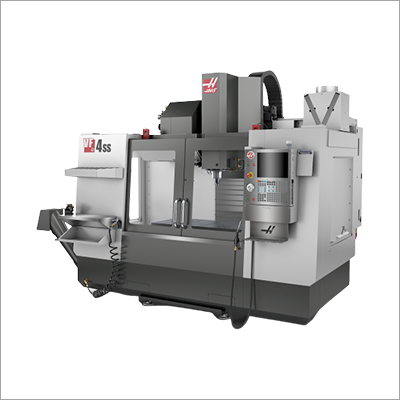

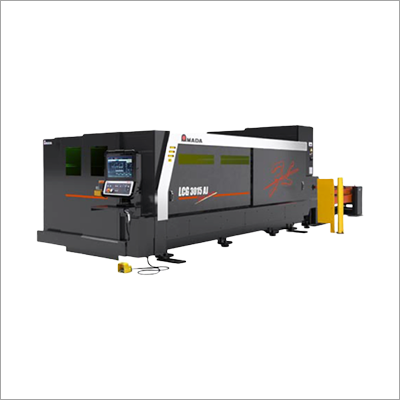

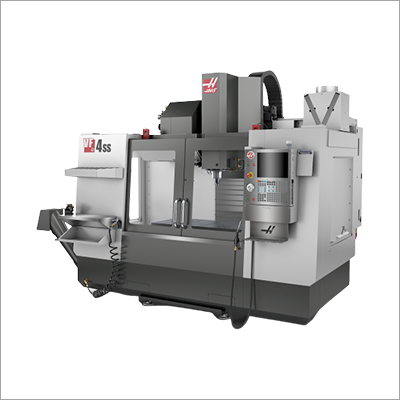

Our equipment ——

About us

Know the Mid

Our business

Aerospace Machining & Assembly

Medical care

Energy and automotive

Industrial Printing equipment

Mid (Dongguan) Intelligen Manufacturing Co., Ltd Copyright 2019